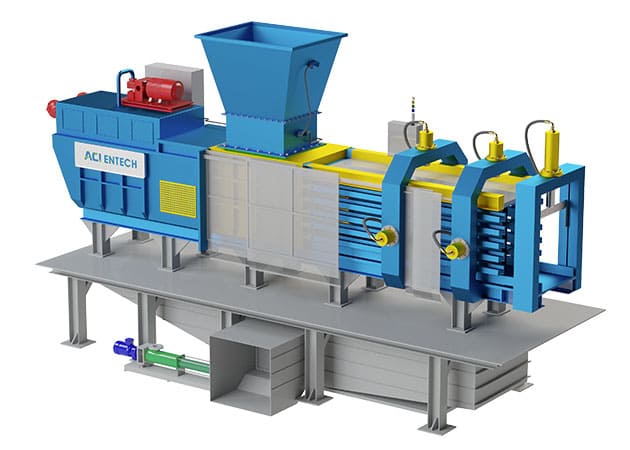

Compacting Dehydrator

Compacting Dehydrator

Dehydrator for Comingled MSW at Tropical Area and Water washed fineshred plastic film

Best applicable for wet MSW dehydration before W2E

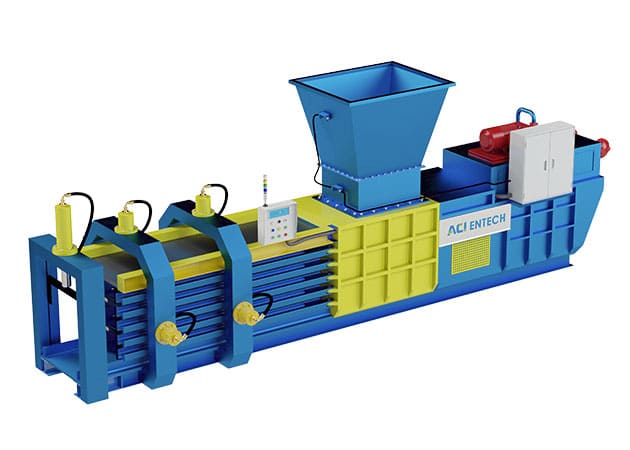

ACI ENTECH Dehydrator is equipped with the press plate and the push cylinder powered by hydraulic unit. This squeezes the liquid out from the waste. Wastes are fed to the hopper by feeding conveyor. When a certain level of the waste is detected by the hopper level sensor, it presses the waste to make the leachate squeezed out. Leachate is gathered in the tank located at the bottom of the Dehydrator while the compacted wastes are loosened by the decompactor and move to the next process. The equipment is operated by PLC panel mounted on the side.

Applications

- Comingled Municipal Solid Waste with high Moisture Content

- Paper Waste with high Moisture Content

- Pulper Sludge from Papermill

- SRF Consumer

Features & Advantages

- Touch Screen with PLC system

- Failure prevention by control system

- Stamping pusher applied for decompacting

- Easy to take out leachate

- East to clean and maintain

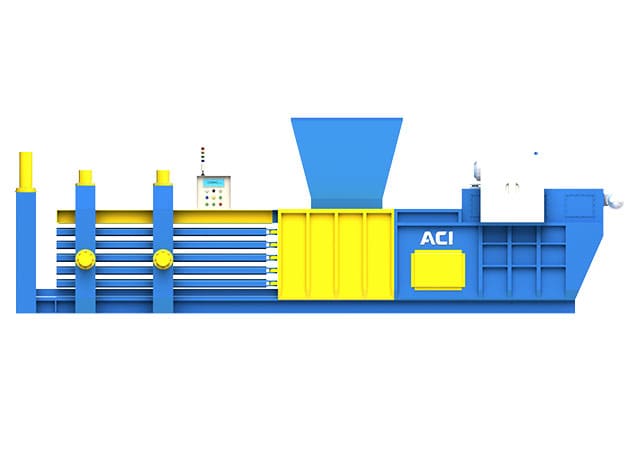

Technical Data

| ACI CD 150 | ACI CD 100 | |

|---|---|---|

| Capacity | 30tph | 20tph |

| Electrical Power | 130kW | 100kW |

| Power Consumption | 75kW x 6Ph & 55kW x 6Ph | |

| Pressure Force | 1,200kN (Normal) / 1,500kN (Max) | 8,50kN (Normal) / 1,100kN (Max) |

| Cycle Time | 21sec | 27sec |

| Pressure Dimension(L x W x H) | 230bar (Normal) / 300bar (Max) | 200bar (Normal) / 270bar (Max) |

| Hopper Size(L x W x H) | 9,000 x 2,420 x 2,360mm | |